Hardwood Flooring

These days, anyone and everyone to be installing hardwood flooring. It’s very frustrating as a consumer to gain any real information as to the pros and cons of each of the different types that are available laminated, solid, engineered since everyone seems to be saying something different. It is the goal of this website to help in sorting this information and increasing customer awareness.

Difference between hardness and durability

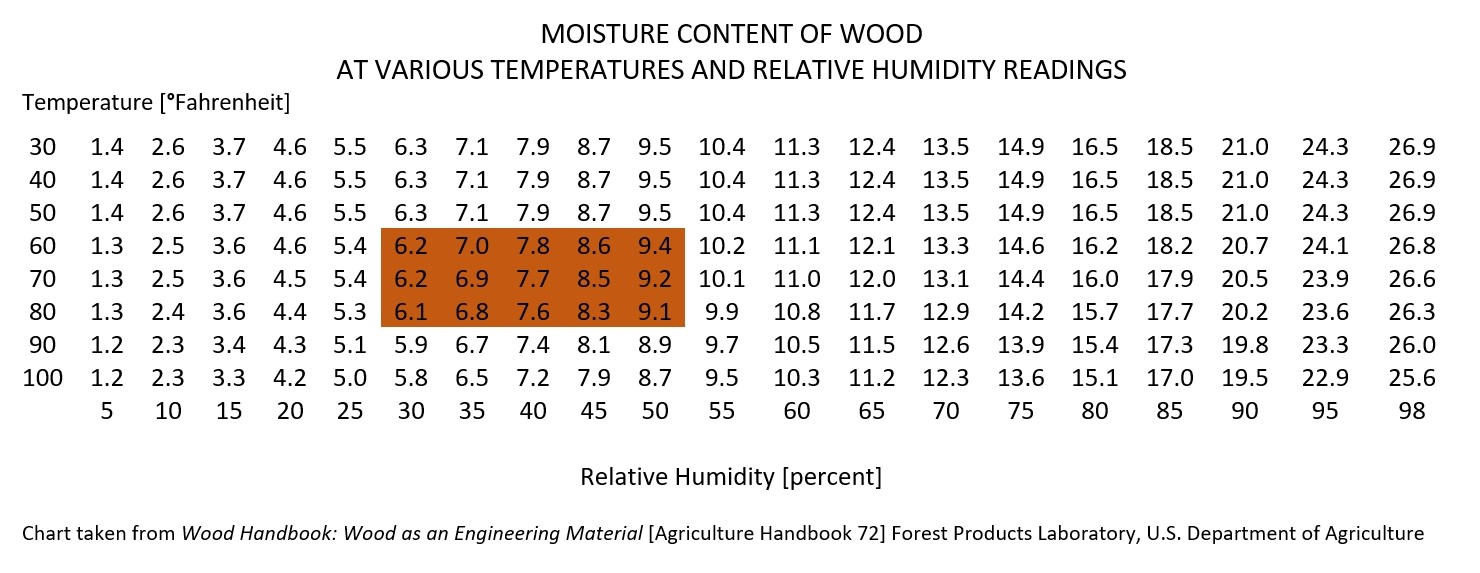

First, lets address the difference between hardness and durability of different types of wood. This is the area that people have the most difficulty understanding. The following chart contains species of wood showing their respective hardness listed from softest to hardest.

Notice that out of the species shown Black Cherry is the softest and Brazilian Cherry is the hardness. It seems simple but if you use only hardness as your guide to durability, you will come to the conclusion that Brazilian Cherry is the harder, therefore more durable than Black Cherry. Wrong! The hardness of wood only has to do with how much denting will occur, not durability.

Hardwood Floor Refinishing

WEBSTER’S dictionary defines durability as: able to exist for a long time without significant deterioration.

Technically, deterioration of a hardwood floor can solely occur if the surface of the floor is wearing down – the finish, not the wood itself. Dents, scratches and similar types of abuse are not relevant when it comes to durability. The more durable a floor is the longer than finish will last before requiring a re-coat. Meaning, it will take more abuse before it really begins to look abused.

The real question that one should ask is how much will the floor dent, not if the floor will dent. See the problem that most people have is because of the new finishes available, most of them include Aluminum Oxide (or some variant thereof) they all now feel that the floor will be indestructible. Unfortunately, these misconceptions are being encouraged by some of the companies involved, but in the end the flooring that we use is wood, and wood dents. Therefore no matter whether it’s Brazilian Cherry or Black Cherry – they will all dent and they will all scratch.

If that’s not enough, the different grains of wood will show the dents to different degrees. The “closed grain” hardwoods – usually Maple, Birch, Beech have such a subtle grain, that they will show more than the “open grained” hardwoods. Now, the “open grain” hardwoods – Oak and Ash, might be a little softer than say Maple, Birch or Beech but since they have such wild grains, the dents will show less. See the chart.

Basically, what we’re saying is that even though the Hard Maple is 12% harder than Red Oak, since the maple is a closed grain wood, while the oak is an open grained product, they will show marking and denting very differently. Not something to be scared of, simply aware of. It all comes back to what I’ve read all above – wood dents.

Hard Maple

Yellow Birch

Beech

Red Oak

Yellow Ash

Wood Floor as a living product

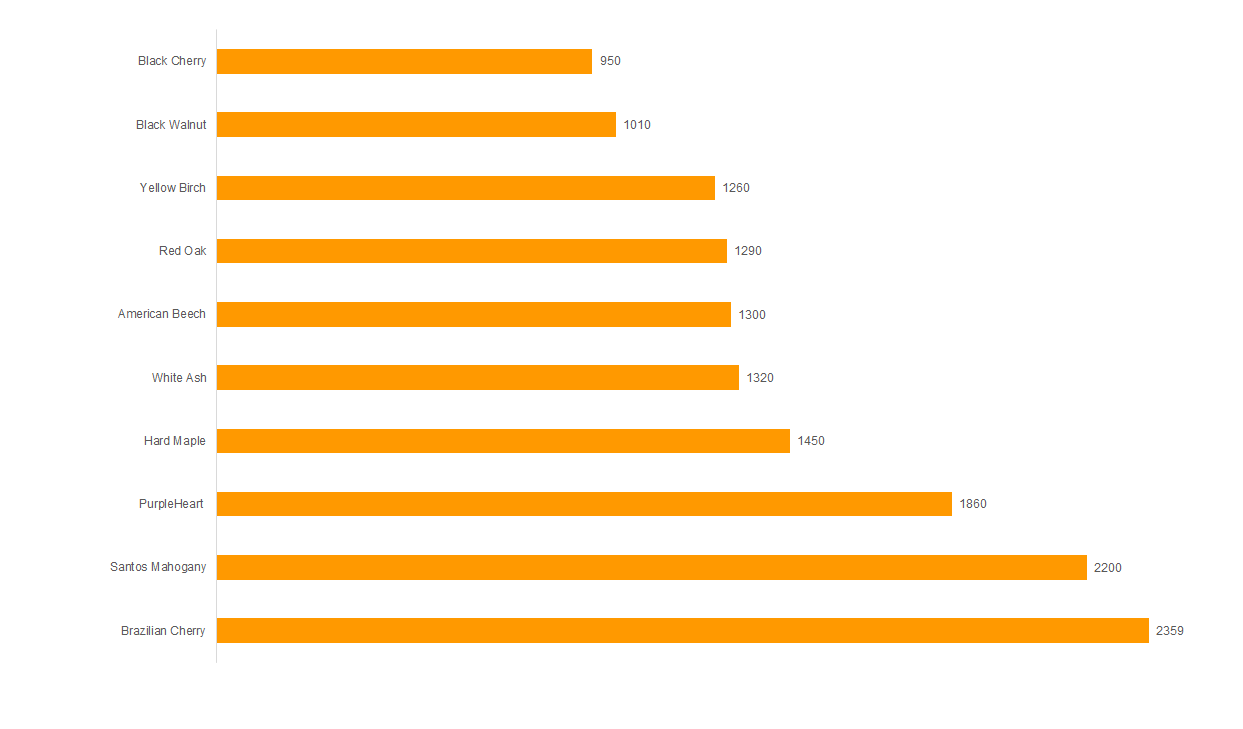

Wood is living product. We consider this to be true because even though the tree has been cut down, it still maintains a cellular structure that is affected by moisture. The moisture to affect the wood could be in the air, the ground, or even our sweat. Different species of wood move more or less because of moisture. This chart shows species from most affected to least.

The numbers themselves don’t mean much to the end user of wood flooring, but basically what the chart is saying, is that a floor made with American Beech will have more movement than a floor made with Purple Heart. By movement, we mean that if the air gets too dry the boards will shrink, and you will notice gaps between the boards. If there is too much moisture in the air, the boards will cup and the edges will be raised.

To minimize the extremes of moisture in our homes use humidifiers and de-humidifiers, but it will only minimize what will naturally happen. In the winters, since our heaters are draining the air of all moisture, the floors will shrink slightly. In the summers, when there is a lot of moisture in the air, the floors will expand back to their original shape.

That covers the more basic points that all consumers should be aware of prior to investing in a new wood floor – Hardness, Durability, and Stability. In the end, no wood is superior to another; it is really a personal choice, as long as the consumer has been informed of their wood’s characteristics.

We are now ready examine the different types of hardwood that are available. There are pros and cons to each of the different types, let’s look at them right now.

Types of Hardwood Flooring

SOLID HARDWOOD

Solid floors are all wood, regardless of width or length, they are one piece of wood from top to bottom Solid flooring gives you a great opportunity for customization. Your choice of species, stains and finishes all contribute to the personalization of a solid floor. This is an excellent choice in most areas of a home on the ground level or above.

ENGINEERED

Engineered flooring is a hardwood wear layer overtop of a base of plywood. The plywood is used for dimensional stability (again – movement) although, it can be a little bit more expensive. The plywood base acts as a stabilizer for the wear layer, so that the floor will move less. Also, the engineered can be nailed OR glued, which does allow it to be used overtop of radiant (in floor) heating systems without problems

LAMINATE

Laminate is a base of MDF – Medium Density Fiberboard (mashed up wood – sort of) with a computer-generated image (picture) of wood flooring on top. Now, the nice aspect to laminate is that it can be used anywhere, and everywhere – most of them are guaranteed against water, and many other dangers that affect wood. It is usually inexpensive (though, of course it does range), and is bought in planks, typically 7″ x 36″ approx. It is floated over a foam or cork underlayment, which allows the floor to move easily. The floors are ‘floated’ which means that they are not attached to the sub floor, just to each other (some with glue, others with a tension system that holds them together).

| PARQUET |

| PARQUET is made up of strips of wood assembled in a square or in a rectangle called a ‘mosaic’. Parquet is quite inexpensive and must be glued directly to the sub floor using a special adhesive. It is available in both a pre finished and a sand-on-site style. Parquet was really popular in the 70’s, but not much in use today. Since they are typically only 3/8″ in thickness, they cannot be refinished more than 2-3 times. |

| What is Vinyl Flooring |

| Our eyes might tell us that vinyl flooring looks exactly like linoleum flooring, but vinyl flooring is markedly different in terms of its composition. Linoleum is completely natural, while vinyl flooring is made up of a high-end synthetic material. Available in many different colors and pattern options, vinyl flooring can be a great fit for both commercial and residential properties. They are available in sheets or tiles that are installed via flooring adhesive. |

The Issue of Moisture – How to choose Hardwood Flooring

Advances in wood flooring during the past few years mean that you now can have wood flooring anywhere in your home or business. Where you want put it, however, will determine the type wood flooring you can use.

Water In Wood

The living tree uses water as the medium to convey food between the roots and the leaves. The living tree, therefore, contains large amounts of water. For every 1 pound of wet, living wood, about 55 to 60 percent is dry wood (that is, cells) and 40 to 45 percent is water. Some of this water is contained in the cell lumen and some is contained within the cell wall itself. Water in the lumen is called free water while water in the walls is called bound water. These terms arise because the free water is not held chemically within the cell, while the bound water is held by hydrogen bonding. Free water evaporates as easily as water from a tea kettle; however, bound water requires a little extra energy for evaporation. Further, and most importantly, when the bound water leaves the cell walls, the cells shrink.

GAPS IN HARDWOOD FLOORS

The beginning of October, customers start calling us up and asking, ” Gee, the beautiful hardwood floors you guys installed for us last summer now have some gaps between the boards, how come??”Usually I begin by saying, ” You ain’t seen nothin’ yet.” As winter progresses the gaps can widen if left unchecked. Let’s take a look back to the summer when the installation took place. Around Chicago land, the relative humidity stays up around 80%-90% from June through Sept. This means the lumber gets delivered to the job-site with a moisture content of about 9%. The floor is then installed and the boards are nailed tight to one another so there are no gaps between the boards. Everything is hunky-dory until October the relative humidity drops like a rock, suddenly overnight, down to a nice comfortable 50%-40% or less. As fall and winter progress we begin to turn on the heat. Now we’re really drying out the lumber. The 9% moisture content drops 30% to 6%. The individual boards begin to shrink in width. Gaps open up. Oh my! Call that *&$#@!&^%$#@! floor guy and yell and scream blah, blah.:’) ” This is normal.” The wood expands and contracts with the seasons. Floors, trim, all the wood moves.” For most customers, at this end of the 20th century, don’t give a hoot about my little nature talk and want a solution to the problem of the gaps. The answer is usually found in adding a humidifier to the heating system, which keeps the humidity of the house at 45% during the heating season. This adds moisture back into the atmosphere of the house, bringing the moisture content of the floorboards back up to around 8%. does the trick 99% of the time. Sometimes even a child’s cold mist humidifier is enough in a small area to solve the gapping problem. A humidifier added to the home heating system runs about $400 and is said to be good for the people in the house as well as the floors.

WOOD FLORING HAS A COMFORT LEVEL, TOO

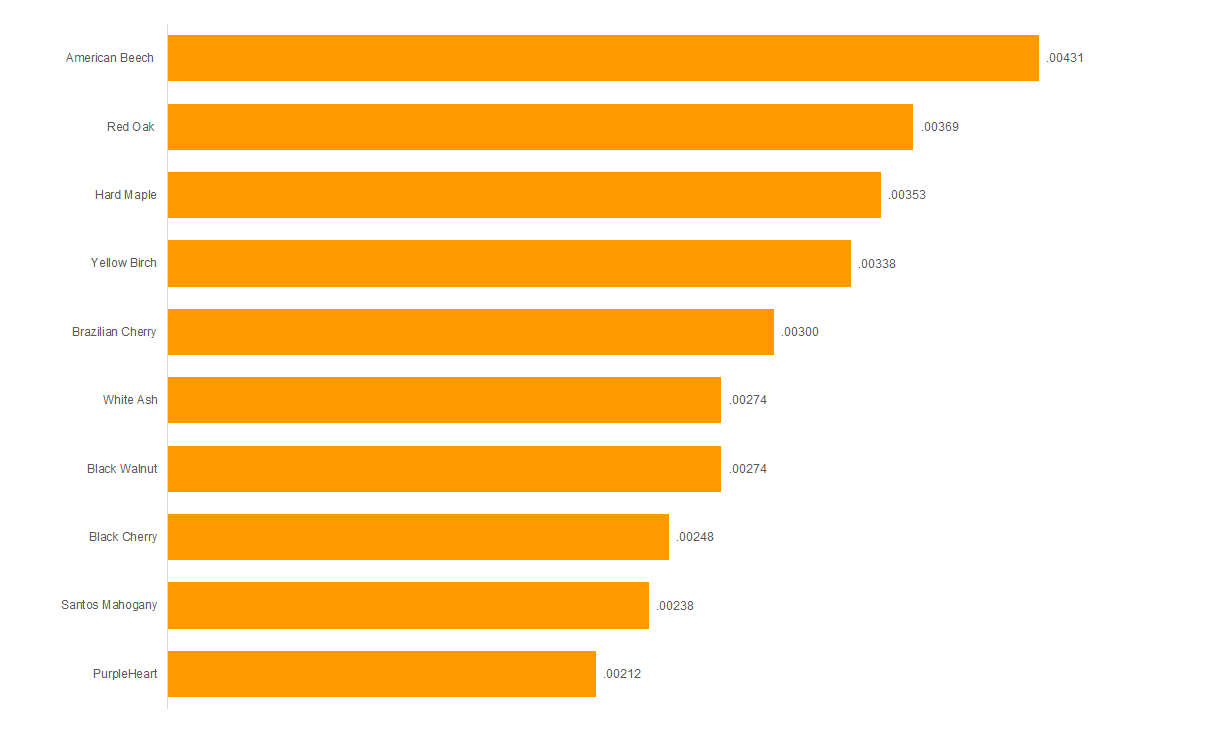

Wood flooring will perform best when the interior enviroment is controlled to stay within a relative humidity range of 30 to 50 percent and a temperture range 60 to 80 degrees Fahrenheit. Fortunately, that’s about the same comfort range most humans enjoy. The chart below indicates the moisture content wood will likely have at any given combination of temperature and humidity. Note the equilibrium moisture contents in the recommended temperature/humidity range (shaded area) coincide with the 6 to 9 percent range within which most hardwood flooring is manufactured. Although some movement can be expected even between 6 and 9 percent, wood can expand and shrink dramatically outiside that range.